Membrane Cleaner Chemical

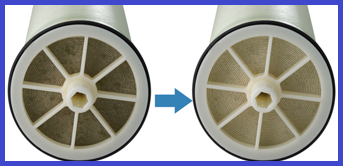

Membrane Cleaner Chemicals are specialized formulations designed to maintain, restore, and extend the operational efficiency of membrane systems such as Reverse Osmosis (RO), Ultrafiltration (UF), Nanofiltration (NF), and Microfiltration (MF). These cleaning agents are essential for preventing fouling, scaling, and performance degradation caused by the accumulation of organic, inorganic, and biological contaminants.

1. Alkaline Membrane Cleaners

Alkaline cleaners are formulated to effectively remove organic contaminants, biofilms, oils, greases, and some types of particulate fouling. These products typically contain surfactants, dispersants, and alkaline compounds (such as sodium hydroxide).

Applications: Organic fouling, biofouling, food and beverage residues.

Recommended pH Range: 10–12.

2. Acid Membrane Cleaners

Acidic cleaners are used to dissolve and remove inorganic scales including calcium carbonate, metal oxides (iron, manganese), and other mineral deposits. These formulations commonly contain citric acid, phosphoric acid, or sulfamic acid, and may include corrosion inhibitors to protect system components.

Applications: Scale removal, metal oxide fouling.

Recommended pH Range: 2–4.

3. Enzymatic Cleaners

Enzyme-based cleaners are used in applications where biological contaminants such as proteins, starches, and polysaccharides are prevalent. These cleaners offer targeted action and are often employed in pharmaceutical, food & beverage, and biotech industries.

Applications: Protein fouling, biofilm in sensitive environments.

4. Specialty Membrane Cleaners

These include oxidizing cleaners (used under controlled conditions), chelating agents for metal sequestration, and low-foam formulations suitable for clean-in-place (CIP) systems.

Applications: Complex fouling conditions, specialized system requirements.

Key Considerations for Use

Membrane Compatibility: Cleaners must be selected in accordance with membrane material and manufacturer specifications to avoid chemical damage.

Cleaning Protocol: Cleaning typically involves a two-step procedure—alkaline cleaning followed by acidic cleaning—to ensure comprehensive fouling removal.

Operational Parameters: Optimal cleaning performance is achieved by maintaining appropriate solution pH, temperature, contact time, and flow velocity.